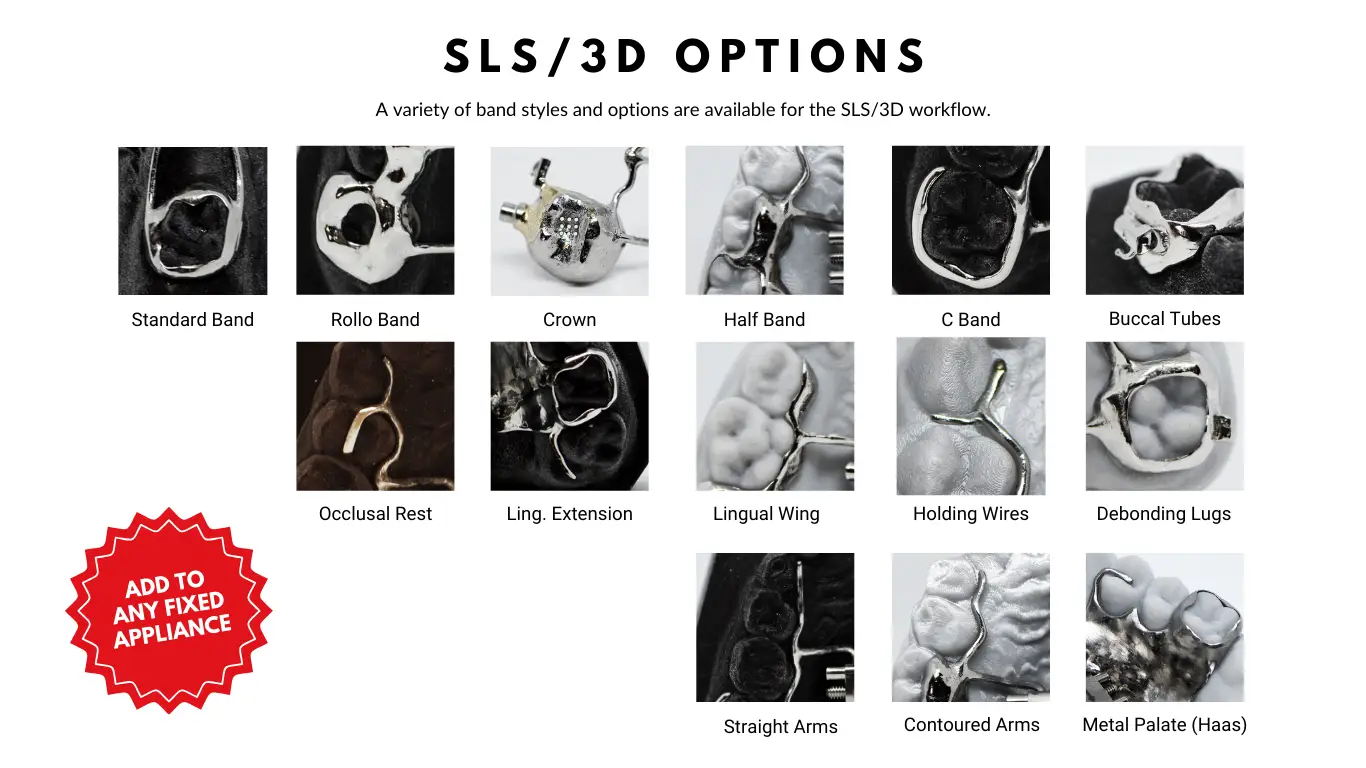

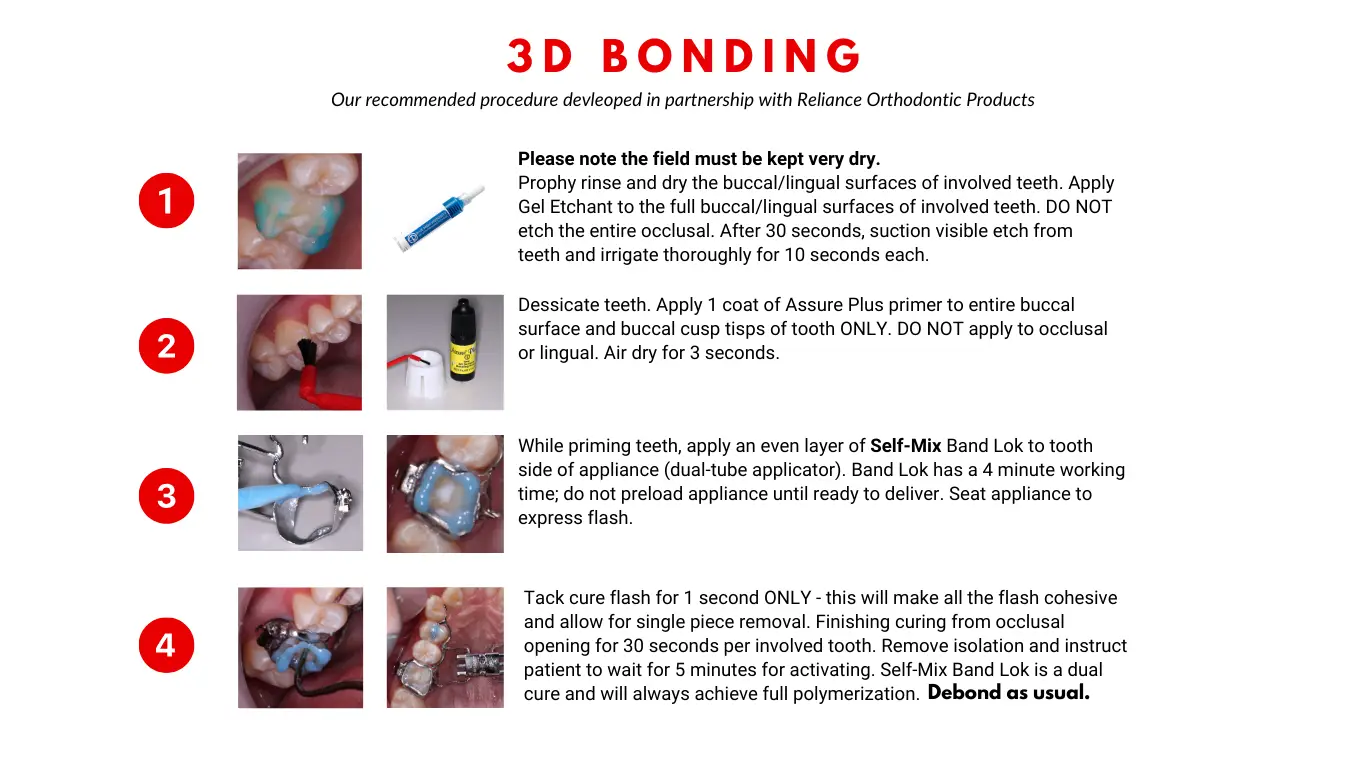

Description

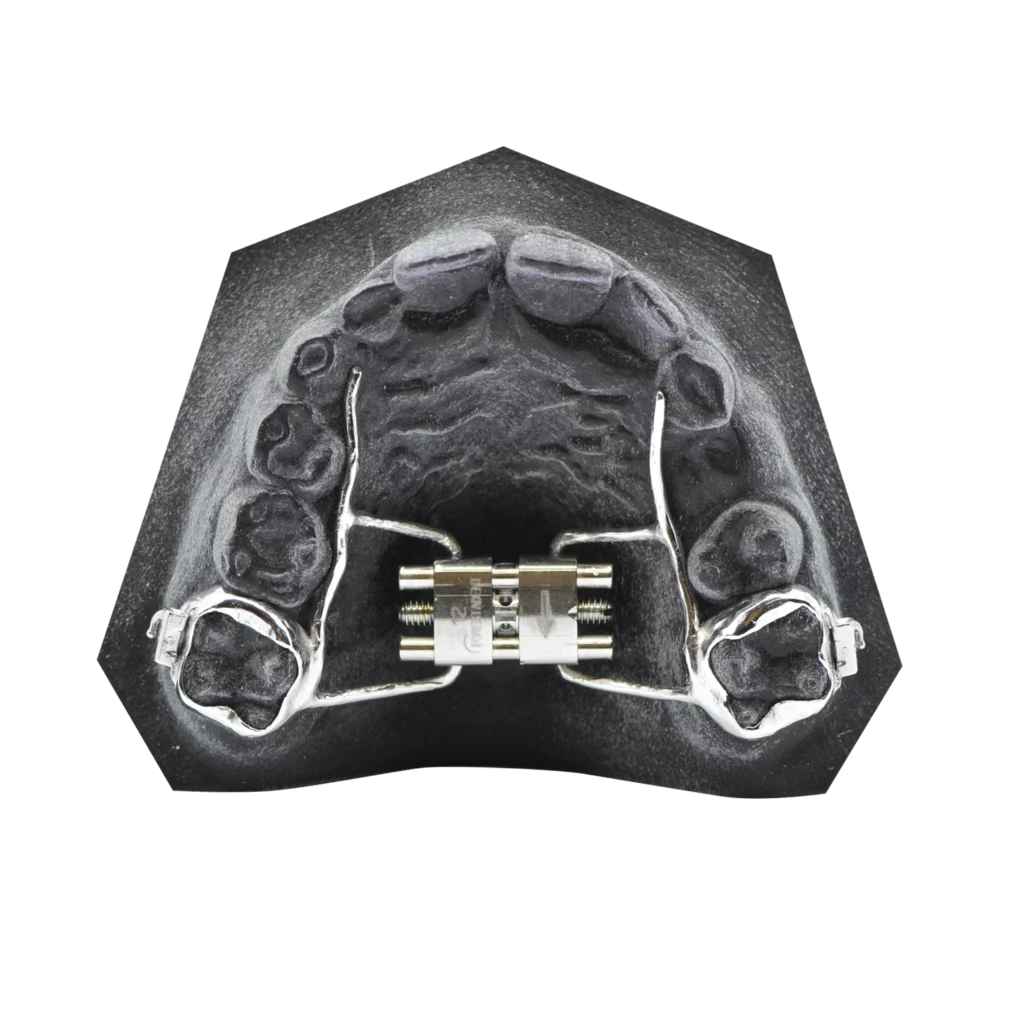

With a patent-pending digital design process, NEOLab is a leader in the 3D Metal Printed appliances space. Our process can design a digital appliance directly on the intraoral scan, creating an unrivaled, custom fit that can be measured down to single microns. In particular, 3D Metal bands are designed in such a way to avoid both subgingival and interproximal interference, allowing you to skip a clinical appointment and avoid spacers entirely. Each designed component is 3D printed in a premium stainless steel, and bands feature an integrated and natural etching from the layered printing process. When paired with your cement of choice and our recommended bonding procedure, the result is a secure hold that can’t be beaten by traditional, mass-manufactured bands.

Banding

Doctor Fit Bands

This traditional method relies on the doctor placing separators, and fitting bands chairside at the second patient appointment. Once the bands have been fit, an impression or scan is taken, the spacers are replaced, and the bands are mailed to the lab to be used in the appliance. At the third appointment, the spacers are removed and the appliance is placed. This is the slowest method of banding we offer, and relies on prompt shipping to ensure there are no production delays.

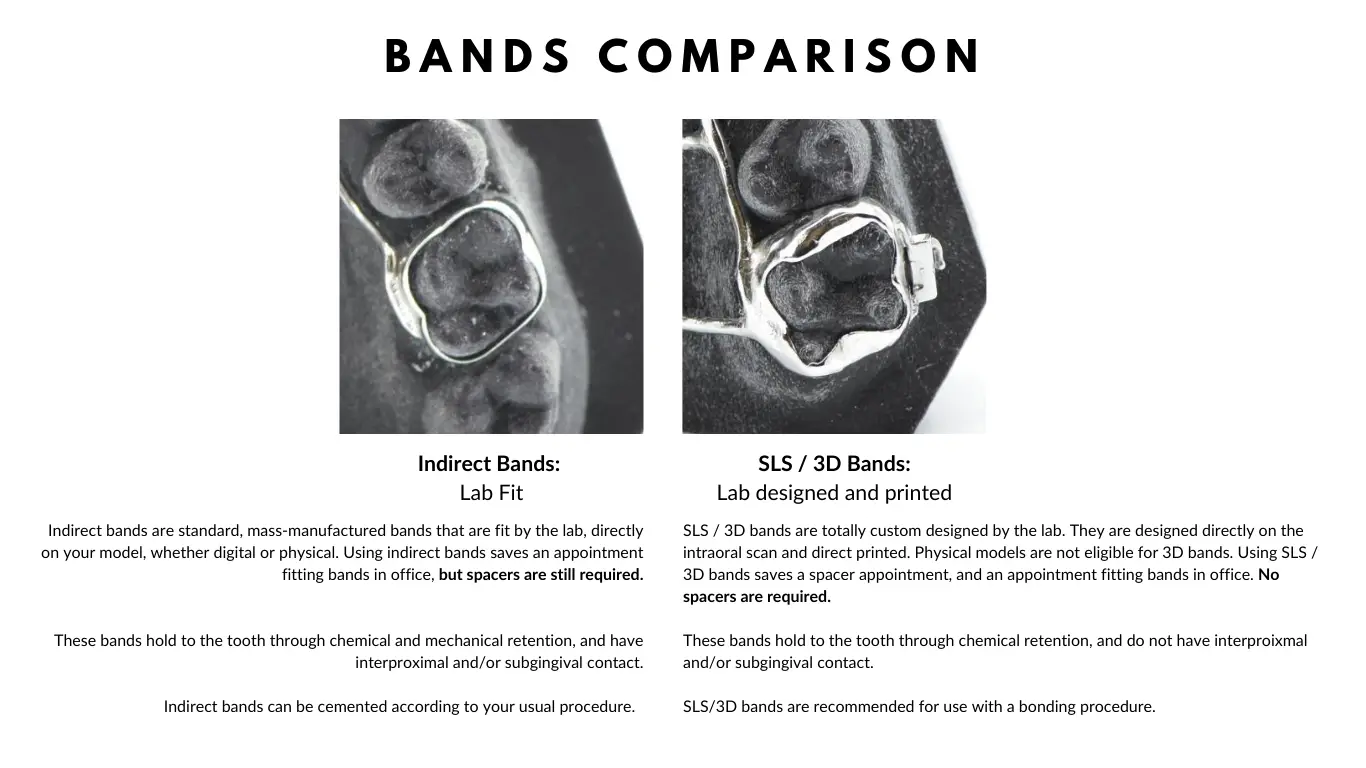

Indirect Banding

NEOLab has long been a leader in indirect banding, and allows the office to skip a chairside appointment. An impression or scan is sent to the lab, and separators are placed. Skilled NEOLab technicians fit bands directly to the model, and fabricate the appliance. At the next patient appointment, the spacers are removed and the appliance is placed. This method of banding removes the waiting period of direct banding, and keeps the case moving efficiently through production.

3D Metal Bands